In-Line Contamination Monitoring System- Shivtech

Introduction: SM-SQ transmitter series ILCM 40 are especially designed to monitor in-line the deterioration of circulated lubricating, hydraulic, transformer, and fuel oils, caused by contamination with water/carbon/mill scale and/or metallic dust. Monitoring the contamination in-line is very critical & highly beneficial for long-term peak performance of the ships engines/systems and preventive maintenance of the plant and machinery

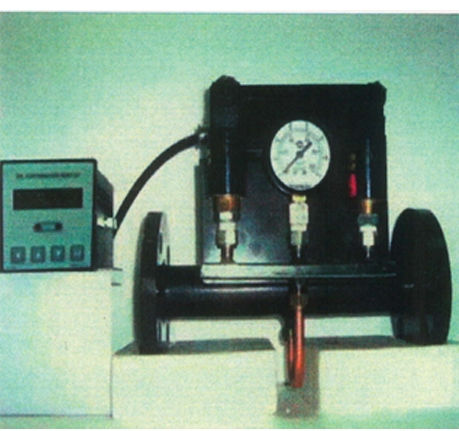

In-Line Contamination Monitor (ILCM 40)

Request for Quotation

Features:

- No moving parts - For high reliability

- Temperature compensated readings - accurate in all conditions

- One-touch calibration - easy setup and maintenance

- Two alarm set points - provision of early warning before damage occurs

- Low Flow detection - ensures correct sampling

- Metallic dust detection - catches bearing metal/mill scale early

Applications:

- Contamination monitoring of circulated oil to/from separators or filters for diesel engines, steam, and gas turbines.

- Return oil condition monitor for hydraulic systems.

- As a 'loss of liquid' detector, to prevent dry running of pumps.

- Water transducer for oil separator control, etc.